Double-Layer Bottom Sealing and Cutting Machine

How Two Layer Bottom Sealing and Cutting Machines Increase Efficiency in Packaging Operations

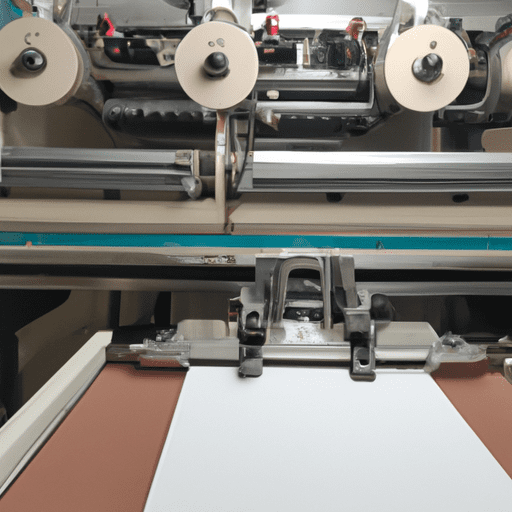

Two layer bottom sealing and cutting machines are an invaluable asset to any packaging operation. These machines are designed to increase efficiency and reduce labor costs by automating the process of sealing and cutting bags. By utilizing two layers of material, these machines are able to create a stronger, more secure seal that is less likely to tear or come apart. This ensures that the product inside the bag is better protected and less likely to be damaged during transit.

The two layer bottom sealing and cutting machines are able to quickly and accurately seal and cut bags in a fraction of the time it would take to do the same job manually. This allows for a much faster production rate, which in turn increases the overall efficiency of the packaging operation. Additionally, these machines are able to produce a much higher quality seal than manual methods, which helps to ensure that the product inside the bag is better protected.

The two layer bottom sealing and cutting machines also reduce labor costs by eliminating the need for manual labor. This is because the machines are able to complete the entire sealing and cutting process without any human intervention. This eliminates the need for additional staff to be hired to complete the task, which can significantly reduce labor costs.

Overall, two layer bottom sealing and cutting machines are an invaluable asset to any packaging operation. They are able to increase efficiency and reduce labor costs by automating the process of sealing and cutting bags. Additionally, they are able to produce a much higher quality seal than manual methods, which helps to ensure that the product inside the bag is better protected. As such, these machines are an essential part of any packaging operation.

The Benefits of Investing in a Two Layer Bottom Sealing and Cutting Machine

Investing in a two layer bottom sealing and cutting machine can provide a number of benefits for businesses. This type of machine is used to create two-layer bags from a single sheet of material, and can be used to create a variety of different bag styles. Here are some of the key benefits of investing in a two layer bottom sealing and cutting machine.

First, this type of machine is highly efficient. It can quickly and accurately create two-layer bags from a single sheet of material, which can save businesses time and money. The machine is also easy to use, and can be operated by a single person. This makes it ideal for businesses that need to produce large quantities of bags quickly and efficiently.

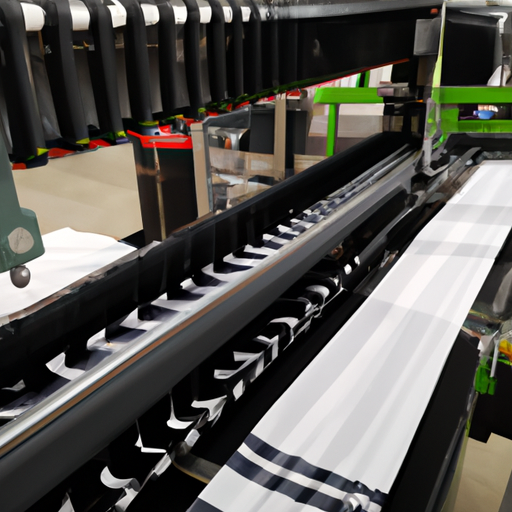

Second, this type of machine is highly versatile. It can be used to create a variety of different bag styles, including gusseted bags, stand-up pouches, and zipper bags. This makes it ideal for businesses that need to produce a variety of different bag styles.

Third, this type of machine is highly reliable. It is designed to be durable and reliable, and can handle a variety of different materials. This makes it ideal for businesses that need to produce large quantities of bags quickly and reliably.

Finally, this type of machine is cost-effective. It is relatively inexpensive to purchase and maintain, and can provide businesses with a cost-effective way to produce large quantities of bags quickly and efficiently.

Overall, investing in a two layer bottom sealing and cutting machine can provide businesses with a number of benefits. It is highly efficient, versatile, reliable, and cost-effective, making it ideal for businesses that need to produce large quantities of bags quickly and reliably.

The Latest Innovations in Two Layer Bottom Sealing and Cutting Machines for Improved Performance

The two layer bottom sealing and cutting machines are essential for many industries, from food and beverage to pharmaceuticals and cosmetics. As such, it is important to stay up to date on the latest innovations in this technology. This article will discuss the latest innovations in two layer bottom sealing and cutting machines and how they can improve performance.

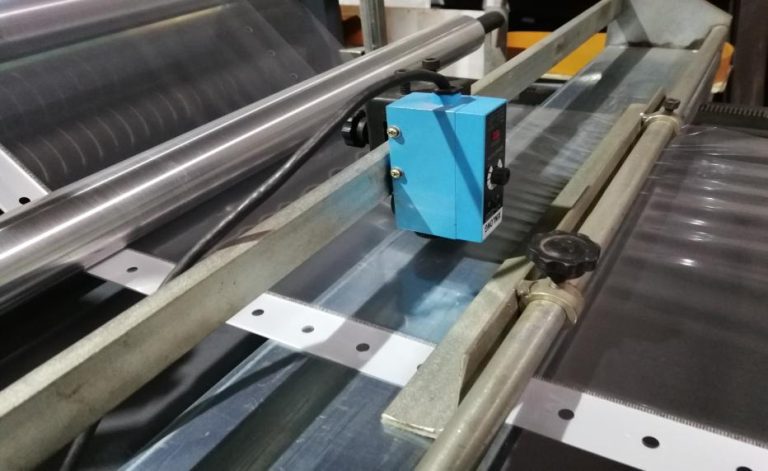

One of the most recent innovations in two layer bottom sealing and cutting machines is the use of servo motors. Servo motors are more efficient than traditional motors, as they can be programmed to run at specific speeds and can be adjusted to accommodate different materials. This allows for more precise and consistent cutting and sealing, resulting in improved performance.

Another innovation is the use of ultrasonic welding technology. This technology uses high-frequency sound waves to weld two layers of material together. This is a much faster and more efficient process than traditional welding methods, and it can be used to create a stronger and more reliable seal.

The use of laser cutting technology is also becoming increasingly popular in two layer bottom sealing and cutting machines. Laser cutting is a precise and accurate method of cutting materials, and it can be used to create intricate designs and patterns. This technology is also much faster than traditional cutting methods, resulting in improved performance.

Finally, the use of advanced software is becoming increasingly popular in two layer bottom sealing and cutting machines. This software can be used to control the speed and accuracy of the machine, as well as to monitor the quality of the seal. This can help to ensure that the machine is running at its optimal performance level.

These are just a few of the latest innovations in two layer bottom sealing and cutting machines. By utilizing these technologies, businesses can improve their performance and ensure that their products are of the highest quality.